The news page

Moderators: MichelleH, Minimalist, JPeters

-

Forum Monk

- Posts: 1999

- Joined: Wed Dec 27, 2006 5:37 pm

- Location: USA

Which direction does water swirl down a drain in Australia?Digit wrote:That's it! I resign, I'm sending my club tie back and taking up train spotting! After years of explaining to wife and kids about the Coriolis effect and why our weather patterns come form the west I have now got to turn the world upside down!

-

Minimalist

- Forum Moderator

- Posts: 16046

- Joined: Mon Sep 26, 2005 1:09 pm

- Location: Arizona

The only thing they said was that the Gulf Stream dipped almost to the equator

The Gulf Stream has dipped down to Arizona and it was cold as a witch's left tit for a while...I can tell you that.

Something is wrong here. War, disease, death, destruction, hunger, filth, poverty, torture, crime, corruption, and the Ice Capades. Something is definitely wrong. This is not good work. If this is the best God can do, I am not impressed.

-- George Carlin

-- George Carlin

-

marduk

Pacific Air

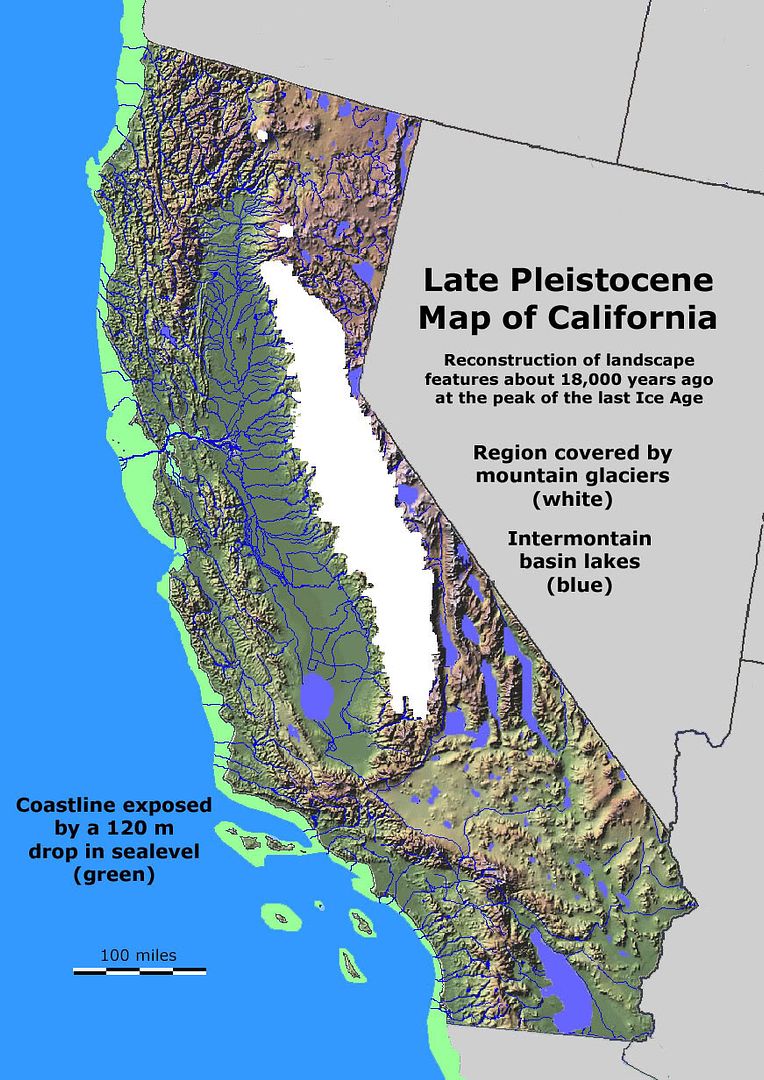

Jesus F. Christ! This isn't news in California ... I already mentioned in another thread that Pacific moist air met glacial air from the Sierras over the southwestern deserts and created a variety of lakes. One helluva lot of rain was dropped. Look at the frikken Pleistocene map of California:In one of the most stark illustrations of how a changing climate can have regional effects, scientists have learned that winds over North America have done a complete 180 since the time of the last Ice Age several thousand years ago.

Winter blizzards and spring thunderstorms today are usually fueled by moisture-laden winds blowing in from the West Coast.

“In this study, we found evidence that during the last glacial period, about 14,000 to 36,000 years ago, the prevailing wind in this zone was easterly, and marine moisture came predominantly from the East Coast,” said lead study author Xiahong Feng of Dartmouth College.”

The findings were detailed today in the online edition of the journal Geology.

People to pay attention!!!! Of course everything has changed! Where are the lakes now? They're all dry! And who's going to listen to a retard named Xiahong Feng anyway? Charlie, get me my club again! .... and I don't mean The Club, we let our membership expire years ago. We need to get everyone's attention again.

Natural selection favors the paranoid

The Club

I have heard so much about The Club here that I plan to design and sell club ties, suspenders, shirts, underwear and beanies on this site. I think they'll sell like crazy ... Michelle do you mind if I do this for profit here? I'll cut you in should you wish!That's it! I resign, I'm sending my club tie back and taking up train spotting!

Natural selection favors the paranoid

http://www.hindustantimes.com/news/5922 ... 030002.htm

From the News Section.The Damascus Swords were fabricated from Ultra-high Carbon Steel, known commercially as Wootz, was produced in South India particularly in the state of Andhra Pradesh around 400 BC,” he said.

“Fabrication of the Iron Pillar, seven-ton heavy and seven meter tall at Delhi known for its amazing corrosion resistance despite exposure to the Sun, wind, dust and rain in the open for more than 16 centuries is another metallurgical marvel of ancient India,” he added.

Dr K Krishnan of Archaeology and Ancient History Department at The Maharaja Sayajirao University of Baroda (Vadodara) delivered a lecture on ‘Ceramic Technology: Its Beginning and Advancements in The Indian Sub-Continent.’ He said that ceramic technology develops with the emergence of the first agricultural communities, designated by the cultural phase ‘Neolithic’, which had a wide distribution in the sub-continent in space and time

I'm also somewhat dubious about some of the assertions I see concerning 'steel'. Iron, with carbon in it, isn't automatically understood today as being steel. It is only steel if the carbon content falls between the agreed figures, Iron with less than that carbon content would still be considered as Iron, but you could get it to take a quite decent edge if you hammered the crap out of it!

-

Forum Monk

- Posts: 1999

- Joined: Wed Dec 27, 2006 5:37 pm

- Location: USA

A quote from the Biblical Archaeology Society Online Archive

Perhaps this is understandable because iron technology is difficult and complicated. As we have seen, in antiquity iron could not be heated to the melting point, so it had to be wrought or forged in a semi-solid spongy mass (or bloom, as it is called). Moreover, this porous mass of agglomerated iron had trapped within its interstices quantities of impurities called gangue, consisting basically of silica. In order to consolidate the metal, it was necessary to hammer or forge the red-hot bloom, thus forcing out or extruding the unwanted gangue. But even when this was done, the resultant pure iron was soft compared to bronze.

The essential factor in the technological development of iron metallurgy was the introduction of up to .8 percent carbon into the red-hot iron, accomplished by a kind of osmosis through prolonged contact with glowing charcoal in the forging furnace. The introduction of this carbon transformed iron from an exotic, semi-precious metal into a metal that would give its name to the age. For carburized iron (iron to which carbon has been added) is, in fact, steel.

The technology is not simple, however. When red-hot carburized iron (or steel) is suddenly cooled off by plunging it into a vat of cold water (quenching), the result includes the formation of material called martensite. Martensite is earth’s second-hardest substance. Only a diamond is harder. The problem is that martensite, though extremely hard, is also very brittle. An object of pure martensite will shatter upon impact.

When carburized iron is quenched, however, the result is not pure martensite. Usually only the outer layers of the object will be converted into martensite; the inner layers will be composed of pearlite, consisting of alternate layers (or lamellae) of ferrite (pure iron) and cementite (a compound of iron and carbon). Just how much martensite will be produced depends upon mass and temperature.

In order to relieve the brittleness of the metal, it was necessary to reduce some of the martensite through tempering; that is, reheating the iron, at temperatures above 150°C, in order to decompose some of the martensite and thus reduce the brittleness of the metal. This resulted in an elaborate trade-off of hardness versus durability that became the hallmark of advanced iron metallurgy.

The technology of working with iron thus became far more complex than anything connected with copper or bronze, and it all had to be learned empirically. No Iron Age smith was aware even of the existence of carbon, an element not identified until the end of the 18th century A.D.; he only learned empirically of its effect. But once these ancient smiths learned that iron subjected to the elaborate heat-treatment of carburization, quenching and tempering was far superior to bronze, a new age was ushered in. Iron was no longer a curiosity but one of the most useful resources in the crust of the earth.

-

marduk